Revolution in Hydraulic Control Technology - Load Port Independent Control Technology - EATON's CMA

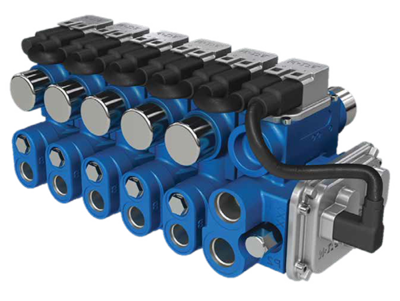

EATON, as a leading global manufacturer of hydraulic components, has launched a multi way valve CMA based on load port independent control technology in recent years.

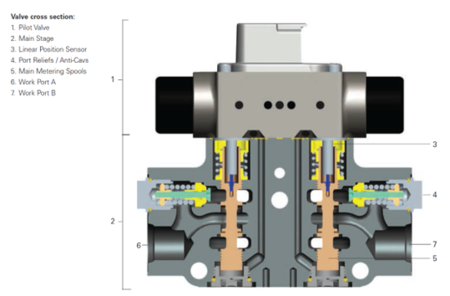

The most prominent feature of CMA is its dual valve core design, which can independently control the inlet and outlet of the actuator, thereby solving the coupling problem of the valve core. Greatly increases the flexibility of control. At the same time, CMA is embedded with pressure sensors for the P/T/A/B four oil ports and temperature sensors for the T port, and the main valve core adopts LVDT closed-loop control. In this way, flow control can be compensated based on real-time feedback of pressure and oil temperature. Implemented pressure compensation and temperature compensation based on electrical feedback, resulting in higher control accuracy.

The pilot stage uses a voice coil motor as an electromechanical converter, greatly improving frequency response while also reducing the control current of the pilot stage. The small control current has profound significance for multi way valves. In terms of traffic allocation (anti traffic saturation). There are three traffic allocation schemes available for configuration selection, and they can be configured through software. Compared to multi way valves that perform pressure compensation and flow distribution through mechanical means, all control of CMA is based on electrical feedback and incorporates more advanced algorithms, making CMA more flexible, accurate, efficient, and rapid. The entire valve communicates with other system components through CAN bus, and has mature control algorithms and configuration software to control CMA. It can be said that CMA for hydraulic control is another innovation in the entire hydraulic control technology.

The basic features of this valve are summarized as follows: (For more technical details, refer to the EATON sample.)

1: Load port independent control technology - based on dual valve cores, more intermediate function groups, programmable implementation, and more control combinations.

2: The integrated P/T/A/B port pressure sensor and T port temperature sensor inside the valve can achieve multiple control methods with temperature compensation.

1) Flow control with pressure compensation

2) Pressure control with flow compensation

3) Intelligent oil return control (achieving stable speed and acceleration control under heavy loads)

4) Flow control for bidirectional loads (achieving flow control under bidirectional loads)

5) : Force/torque control

6) Load damping function

3: The multi actuator flow distribution function is based on electrical feedback - more flow distribution modes can be configured through software, resulting in higher flow distribution accuracy.

1) : Proportional reduction of traffic mode

2) : Same as absolute flow reduction mode

3) : Set priority mode

4: Security Configuration

1) Pipeline rupture protection

2) : Fault tolerance function

3) Online diagnosis - full pressure flow monitoring

5: The main valve core is equipped with LVDT for higher control accuracy, and the working oil circuit is equipped with anti backflow valve/makeup valve.

6: The pilot adopts a voice coil motor with higher frequency response and lower power consumption. Higher frequency response.

7: Suitable for load sensitive systems/quantitative systems.

8: Control signals are provided through the CAN bus and manual override is optional.

9: 90L/min; 200L/min; 440Bar

As a professional partner of Eaton Fluid, Hunan Honghui Technology is dedicated to sharing CMA engineering machinery intelligent multi way valve products with a wide range of engineering machinery customers, improving the intelligence level of engineering machinery equipment.